Problem

Electronic systems are vulnerable to corrosion with both silver, copper and solder elements susceptible to corrosion. These metals tend to tarnish rather than rust which results in hot spots forming and the risk of the electronic device failing. A specialised communication provider of equipment to both Government and military clients globally were seeking to protect various electronic systems.

Solution

Vapour capsules provide targeted, long life corrosion protection. Easy to install, non toxic and leaving no residue the vapor capsule ensures that the equipment continues functioning as it should with no tarnish or corrosion present. Protection is offered for either a one year or two-year period. Ideal for use where reliability is of the utmost importance.

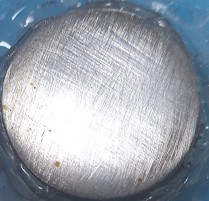

The table below shows test results under MIL-STD-3010 method 4031 for vapr inhibitor ability. Evidence of corrosion on the control sample is clearly visible and distinct to the samples protected by VCI

| Product Sample | Results | Test Material Results |

| Control | Grade 0, corrosion present |  |

| (S) Sample | Grade 2-3, 3, 3 Little to no corrosion |    |

Benefits

VCI vapor capsules offer the following benefits:

- Longer equipment life and sustained reliability

- Eliminates hot spots and reduces the risk of electrical fire

- Reduces operating and maintenance costs due to improved conductivity

- Reduced downtime and fewer repairs

- Maintains a clean, high-quality surface with no need to apply circuit board coatings making test and trace activities simple

- Multi-metal protection including ferrous and non-ferrous metals (silver, copper)

- Equipment in storage is ready for instant use with no need to pre-prepare asset for deployment